- Last updated

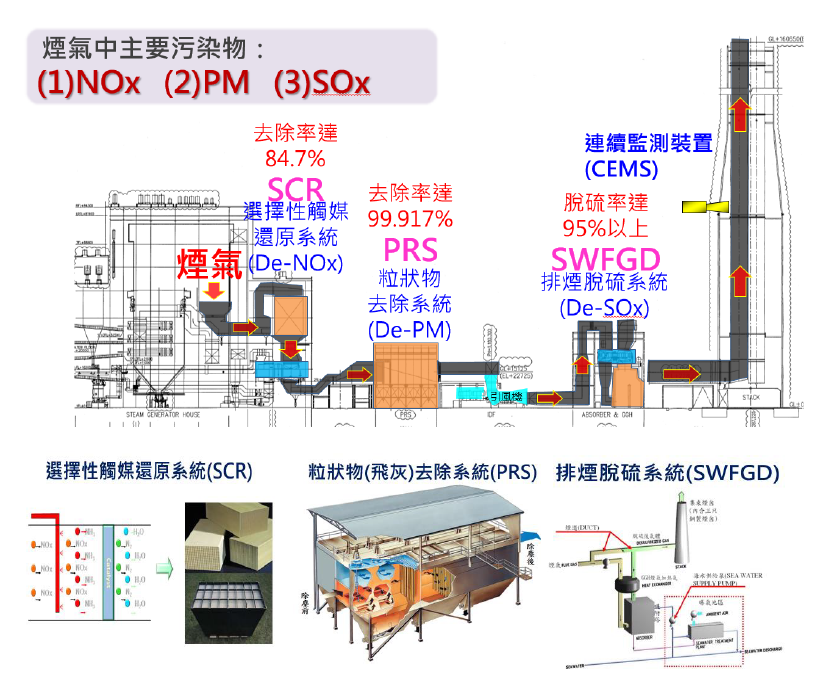

After burned in the boiler, the air pollutants like as the sulfur oxides, nitrogen oxides and particulate matter will be generated from the coal. The following is an explanation of the air quality control system.

AQCS for Coal-Fired Power Plants (PDF)

Nitrogen Oxides Control Technologies

NOx control technologies may be placed in two categories: low-NOx burners (LNB) and selective catalytic reduction (SCR). LNB and over fire air system (OFA) reduce the amount of NOx produced in the primary combustion zone. In contrast, SCR reduce the NOx present in the flue gas away from the low-NOx burners.

SCR is a post combustion NOx reduction technology in which NH3 is added to the flue gas, which then passes through layers of a catalyst, the NH3 and NOx react on the surface of the catalyst, forming N2 and water. NOx reductions achieved at these applications accounted for 80%, the following is the explanation of the process.

Particulate Matter Control Technologies

The following picture shows that it can remove more than 99.8% particulate matter through the Electrostatic precipitator (ESP).

The particulate matter collected by ESP called fly ash, which widely being used in constructing material.

Sulfur Oxides Control Technologies

Flue-gas desulfurization (FGD) is a set of technologies used to remove sulfur dioxide from exhaust flue gas of coal-fired power plants. The FGD may remove 90% percent or more of the sulfur oxides, the following is the flue-gas desulfurization.

FGD used by coal-fired power plants remove sulfur from combustion gas and produces "FGD gypsum," which is chemically nearly identical to mined natural gypsum and provides a wide-range of environmentally friendly applications.

Processing or Improved Efficiency

In order to decrease the environmental impacts caused by the air pollutants emissions from the thermal power plants, TPC has to reinforce the renewing of the relative devices and promote the betterment work of the Air Quality Control System. TPC has been implementing Taichung power plant #5-#10 AQCS retrofit project.

In order to grasp the condition of the emissions immediately, all the power plants are equipped the continuous emissions monitoring systems (CEMS) to measure the emissions, to meet with the standard and decrease the environmental impacts.

The Renewing of the Linkou and Dalin Power Plant

TPC has renewed Linkou and Dalin power plants. The new generator is the ultra-supercritical coal-fired unit with 800MW. To meet the rigid standards and to demonstrate the determination of environmental protecting, the new generators are equipped the high effective Air Quality Control System (AQCS), such as Fabric Filters (FF), Selective Catalytic Reduction (SCR), and the Sea Water FGD (SWFGD).

Take Linkou power plant as an example, the total investment is about NTD 152.5 billion. and the environmental works occupy 30% of the total investment, which is about NTD 40 billion. It shows a significant change in environmental improvement. The emissions of the particulate matter, sulfur oxides and nitrogen oxides from the renewed generator are 10mg/Nm3, 15ppm and 23ppm.

Units No.5~10 Air Quality Control System (AQCS) Retrofit Work Project of Taichung Power Plant

Unit No. 5~10 of Taichung Power Plant have achieved outstanding performance since they were put into operation in 1996. However, due to the increasingly stricter standards of the central and local environmental protection regulations in recent years, the existing units will be retrofitted to supply the stable power and meet the emission standards in the operation lifetime by improving the air pollution control equipment and reducing various pollutants - NOx, SOx, and PM.

The improvement items include:

- Reconstructing the selective catalyst reduction (SCR) and replacing the honeycomb catalyst to convert NOx into water and N2 significantly.

- Installing a media gas-gas heat exchanger (MGGH): Upgrading the existing rotary gas-gas heat exchanger (GGH) to a non-leakage MGGH, and relocating the cooler side of the MGGH to before the electrostatic precipitator (ESP) can reduce the flue gas temperature, decrease the volume of flue gas, lower dust resistance, and enhance the dust removal efficiency of the ESP.

- Updating the spraying system of the wet flue gas desulfurization (FGD) scrubber and replacing internal components to simultaneously enhance SOx removal efficiency and equipment operational reliability.

- A new wet electrostatic precipitator (WESP) has been added. Because of the characteristics of "humidification" and "washing", WESP can further capture finer particles and aerosols in flue gas.

Through comprehensive improvements, the air pollutant emission concentrations can be lower than the standards for air pollutant emission from coal-fired power plants by Taichung Environmental Protection Bureau (implement on 2024/01/01):

- NOx: the annual average emission concentration will be reduced to 20 ppm.

- PM: the annual average emission concentration will be reduced to 5 mg/Nm3.

- SOx: the annual average concentration will be reduced to 10 ppm.

Before and After Retrofit for Units No. 5 to 10 of Taichung Power Plant.png?rmode=max&width=500)